ADVANCED MATERIAL STRUCTURES

Plastic Reinforcements(ACMFG) has a 38 year history serving major aerospace OEM’s, military organizations, architectural designers, major airlines and the entertainment industry. Manufacturing composite panels, complex laminates, mechanical and bonded assemblies…

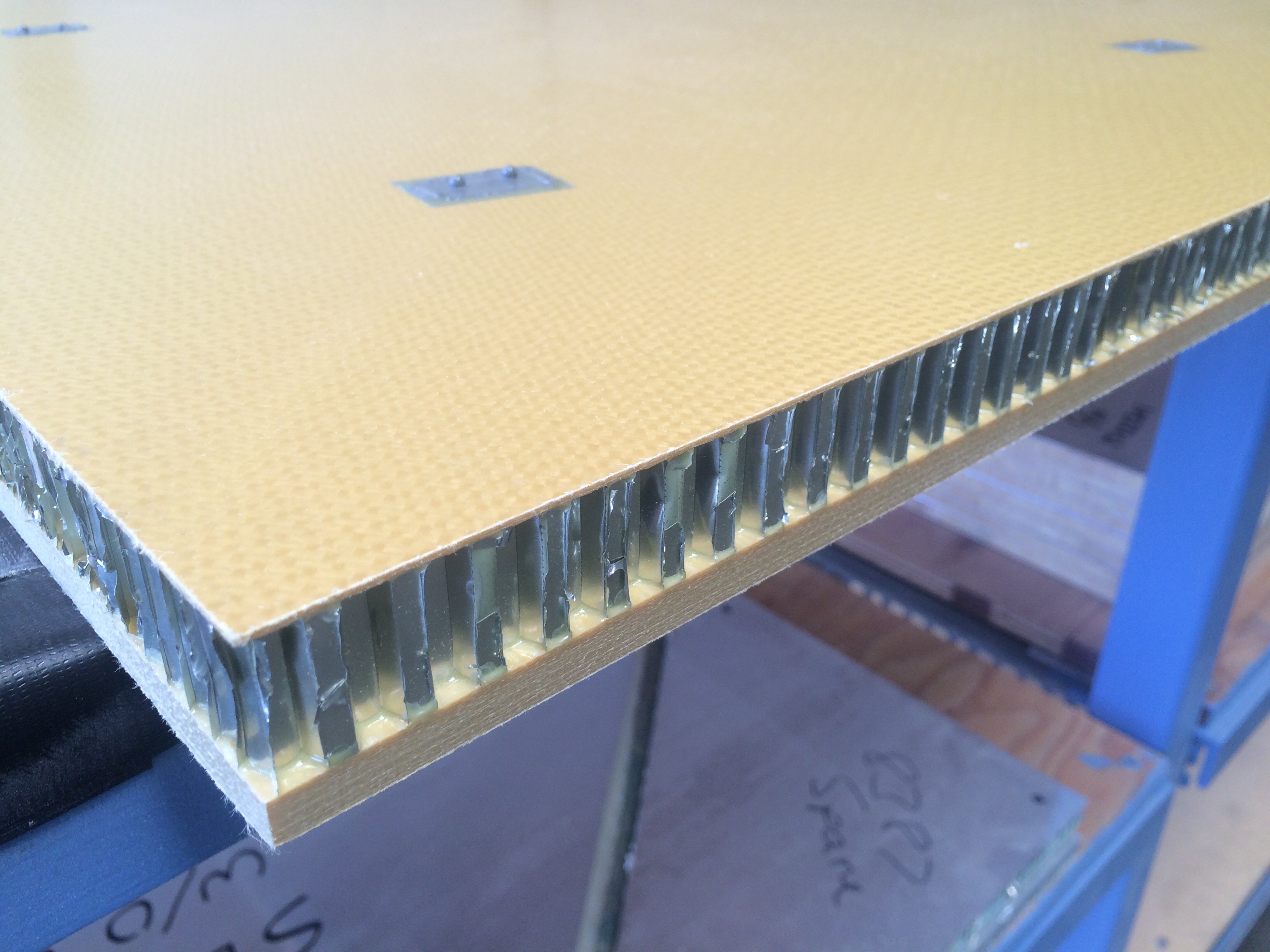

Specializing in Honeycomb Structures

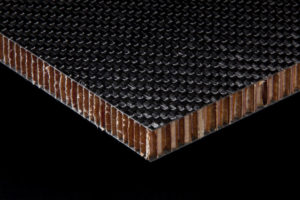

Advanced Custom Manufacturing has experience with various aluminum and composite materials allowing us the ability to produce a custom panel. The part meets a customer’s requirements which require specific weights, mechanical performance, and cost….

Defense Composite Panel Structures

Our composite materials fabrication abilities includes panel fabrication, chemfilm/paint, insert installation and edgefill for a component that is installation ready. The panel structures can be flat and processed in our heated platen presses, or contoured and vacuum bonded in one of our walk in ovens.

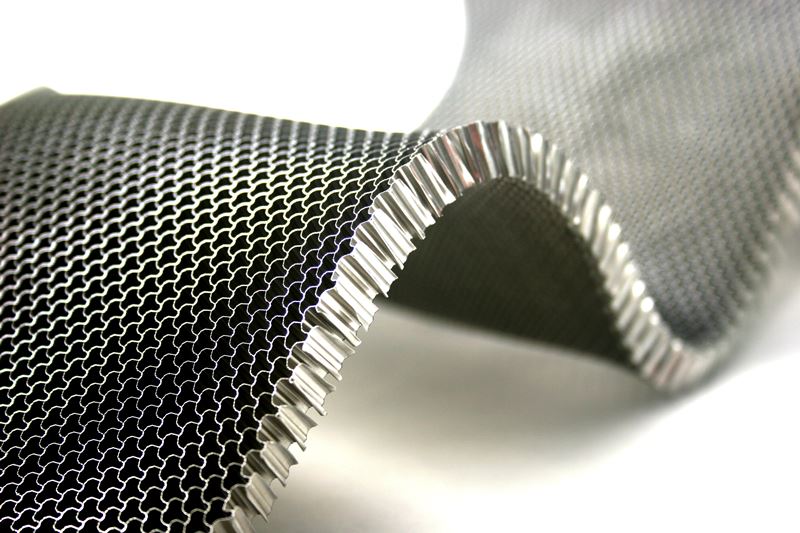

Honeycomb CORE Machining

Advanced Custom Manufacturing can offer CORE machining, lay up and bonding for our customers. Honeycomb CORE profiling and/or fabricated honeycomb CORE components adds ease and precision to the assembly process. This is our CORE competency and makes us a one stop shop for all of our customers bonded assembly needs.

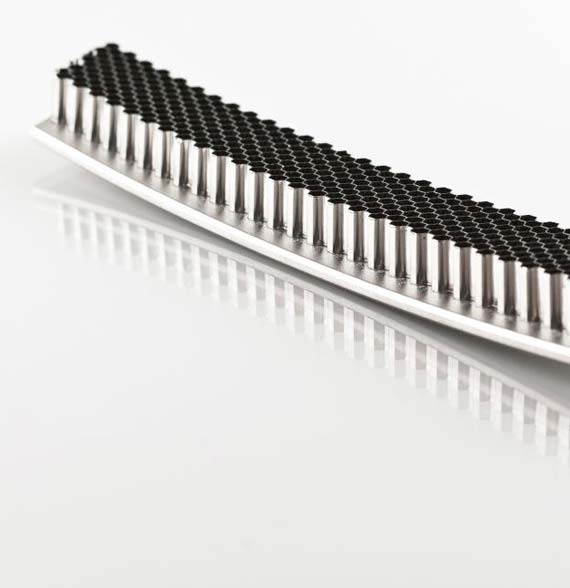

Protective FOD Shields and FOD Mat

The FOD Shield is heavy-duty rubberized work mat engineered to provide the most technically advanced protection for costly composite structures that are subject to impact. The FOD Shield has been designed to reduce impact by up more than 6 times the weight of the object falling.

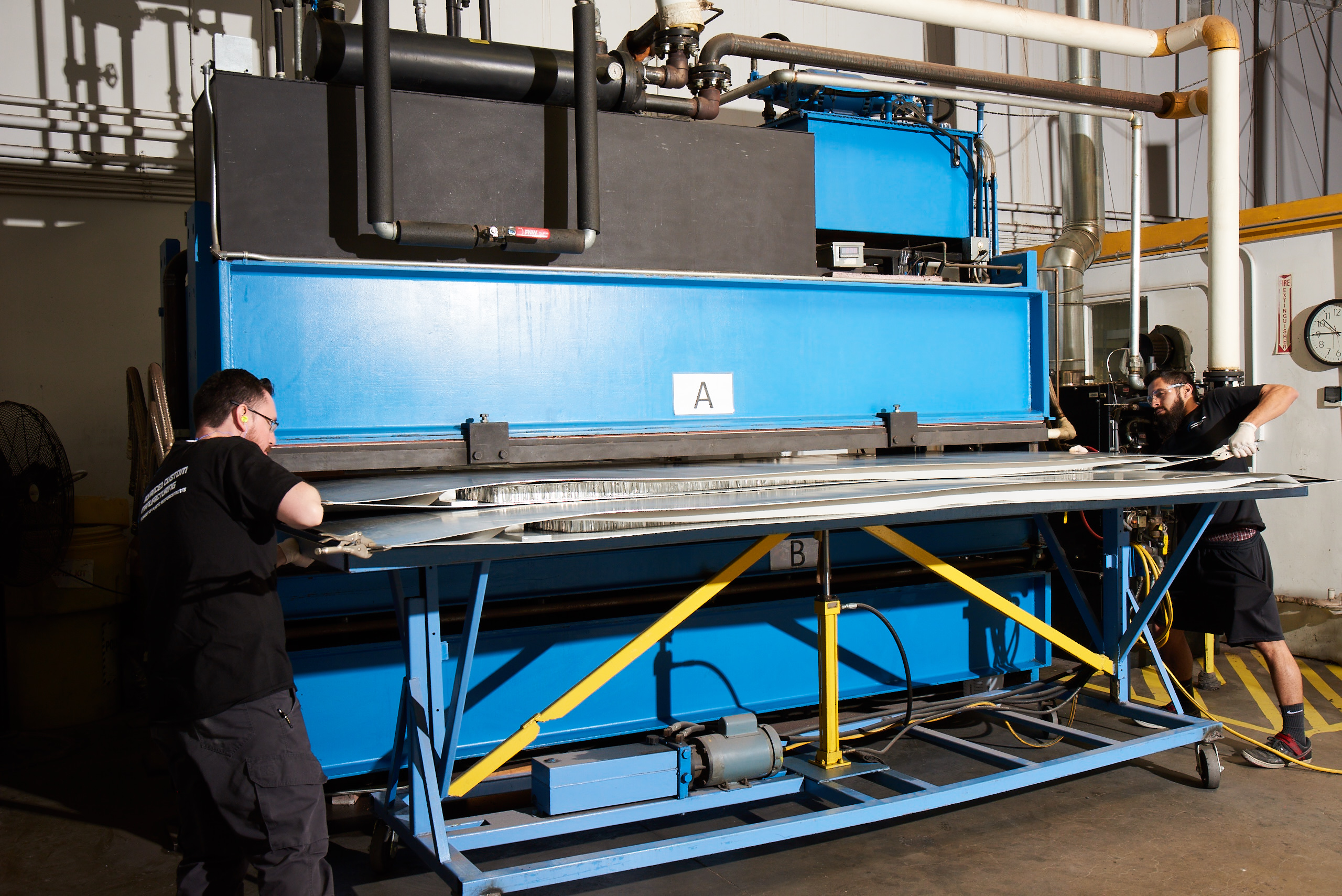

NEW PRESS!!!

SDM Laminator 600 Ton, 4 opening 5’ x 12’ composite press. SDM stage III cooling system. Automatic controls with data acquisition designed to monitor, document and control processing. This system eliminates human errors and assures precise repeatable controls for heating and cooling. Maxramp II platens, state of the art platens and can transition at 5 F per minute which will equalize to plus/minus 2 F. This press excels at producing extremely flat panels with the highest physical properties.

FOD SHIELD

Our FOD Shield is a heavy-duty rubberized work mat engineered to provide the most technically advanced protection for costly composite structures that are subject to damage upon impact.

FABRICATED PRODUCTS

Advanced Custom Manufacturing has a broad knowledge base in composite materials. We fabricate honeycomb sandwich panels made from a variety of materials including Fiberglass, Kevlar,

COMPANY PROFILE

Plastic Reinforcements (ACMFG) has a 38 year history serving major aerospace OEM’s, military organizations, architectural designers, major airlines and the entertainment industry. Manufacturing composite panels, complex laminates, mechanical and bonded assemblies for defense, avionics, aerospace, sporting goods, marine and green energy.

Committed to supplying parts and service that meets customers’ requirements. Quality requires continuous improvement in all areas with an error-free goal