FACILITIES

A metamorphosis that has been in process since 1984 has lead to a complete in-house manufacturing facility. Our 20,000 sq. ft. building encompasses the entire spectrum, from customers composite design, manufacture to final inspection; beginning with initial bonding, hardware attachments, to Mil-Spec quality paint. Advanced Custom Manufacturing is your ‘Composites Solution’.

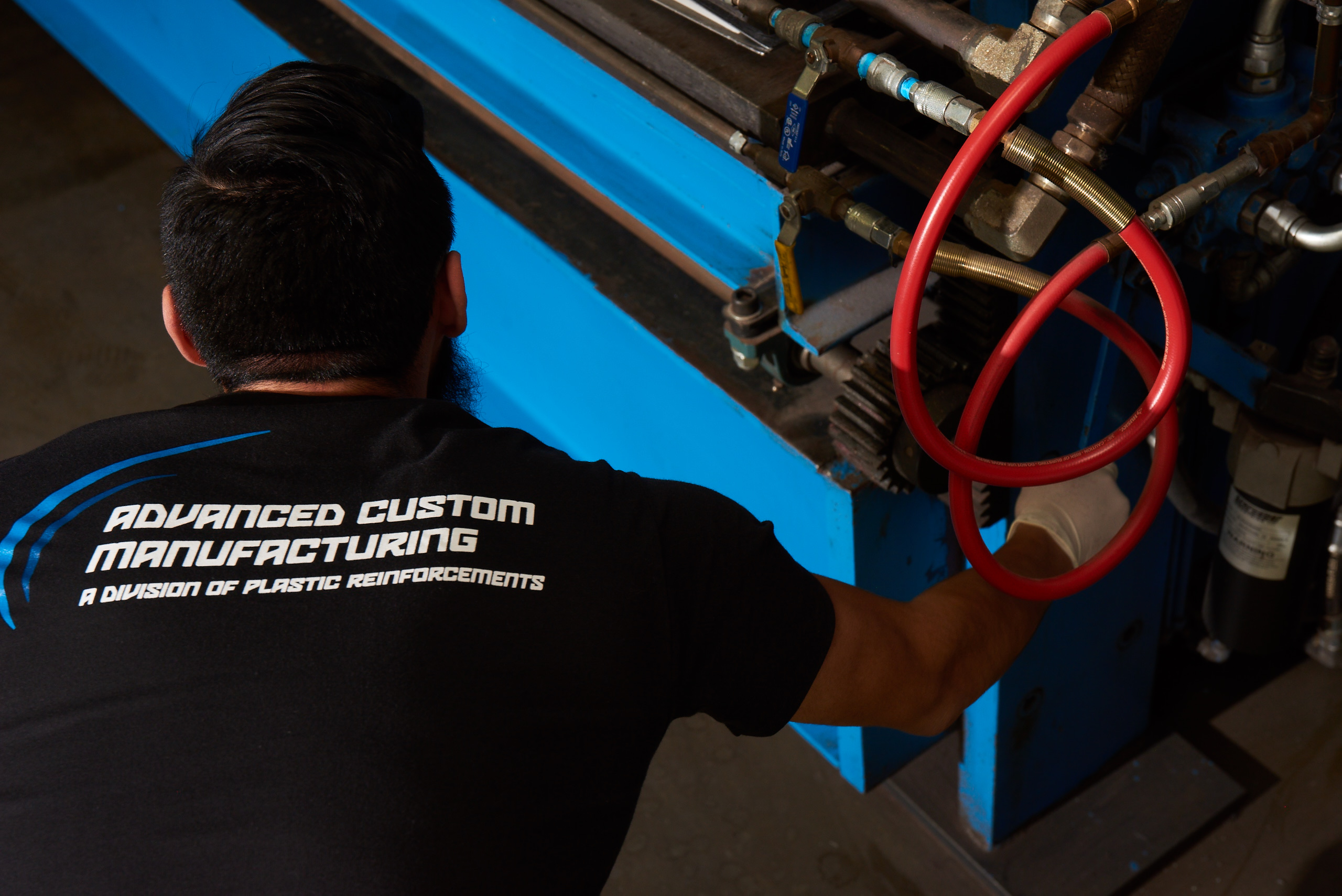

Here is a sample of our basic equipment:

- 4′ x 24′ heated hydraulic press, 2 opening

- 5′ X 12′ heated hydraulic press, 4 opening

- 2 8′ x 12′ walk in ovens with vacuum bag capabilities

- 2 x 0 degree & 40 degree walk in freezers

- 6′ x 12′ surface table

- QC area and equipment